(2600 words)

All recipes for charges are given by weight. Normally, to 0.1 grains.

Each powder has a different density and a different required charge.

Powders come in different granule shapes. There are flakes. There are cylinders, formed by pushing wet powder through round holes, then cutting them into small cylinders. Finally, there are spherical granules.

The surface area of a granule is the biggest factor in how fast a given powder burns. The same composition, in different shapes, will burn at different rates.

For each lot of powder, the density for that powder should be the same, on average. For each can of powder, the density will be the same.

The volume required to for a charge is the density of the powder multiplied by the weight of the charge.

There are powders that take small charges, some take larger. For example, the Hodgdon recipe for 45ACp says that IMR Blue can be used with a starting charge of 9.0 grains. They also say that you can use Clays with a starting charge of 3.7grains.

There is only a 0.3grain difference between the starting charge and maximum charge when using Clays. This is not a lot of room for error.

There is a bit more range for IMR Blue. Regardless, the point of this is to let you know that we are measuring small values accurately and repeatably.

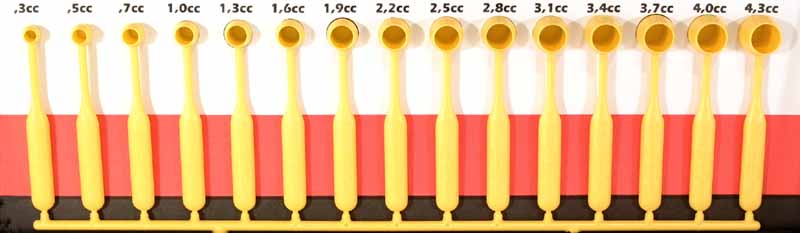

If you decide on a powder that can be measured safely with the Lee volumetric scoops, you can start there.

To use the powder scoops, you will need a copy of Modern Reloading by Richard Lee, or you will need a recipe from one of the recipe cards that come with Lee die sets.

There are several issues with this method, the first is that there are a limited number of “weights” you can get from this limited set of scoops. The next is that you are unlikely to be as consistent with leveling as you might want to be.

What this means is that the repeatability might not be where you require it to be.

But here’s the thing, we do use volumetric measuring metering systems for powder. Different companies have different versions, but they look something like the following:

This gizmo, and others like it, have a variable volume that powder flows into. When you “throw” the charge, that volume is dispensed through the bottom spout, into a case or other container.

Because it has a fine pitch screw with hash marks around the barrel, you can adjust the volume as you need to get good throws.

The issue with these is that they are not standalone devices. They need an accurate scale to measure the amount of powder that was thrown, by weight. You adjust the volume, throw and measure another charge, repeat until you get the correct charge.

Then be prepared to check the charge weight occasionally to make sure it hasn’t changed.

Because the powder sits on top of the “scoop”, the amount of pressure changes as the powder level goes down. This can change the amount, by weight, that is thrown with each charge.

In addition, some granule shapes do not like to feed through these types of powder dispensers. The cylindrical shape is the worst. Often, a granule will get caught at the shear line. As the drum rotates, the granule is either cut or forced to one side of the shear line or the other.

It can be a beast to work with some powders in this type of situation.

Before we get to all these fancy things, we need to learn how to measure powders accurately and repeatably. You might wish to throw “rapidly” into that, but work on smooth, fast comes naturally.

Throwing Your First Accurate Charge

We will be using three devices to get our accurate charge, a scale with powder dish, a trickler, and a measuring spoon/scoop.

This thing is a trickler. You fill the center with your powder. As you rotate the dispensing tube with the green knob, powder is transferred from the reservoir to the tube. The tube has threads in it. Those threads carry the granules of powder to the end, where they drop off.

With this device, you can trickle out powder a grain at a time.

This is a mechanical scale with a powder pan. A trickler can be placed so the dispensing tube is over the powder pan. As you rotate the green knob, grains of powder fall into the pan. If you pay attention, you can get exactly the charge you require.

These scales are quite good. They are designed so that they don’t take long to stabilize after you add weight to them. They can easily be read to 0.1 grains. In some cases, they are more accurate and produce repeatable values.

We could stop there, but I do not think you would be happy twisting that knob for 5 minutes to get to your charge.

Instead, we use plastic (no sparking) spoons are scoops. You can even start with the Lee Scoops. At $13.00 for all of those scoops, it isn’t a bad idea.

Now we begin.

Take your smallest scoop or spoon and add that much powder to your powder pan. Wait for the scale to settle and read the weight.

Divide your target weight, in grains, by the weight of that smallest measure.

Using totally made up numbers, I want a charge of 23 grains. I measure out 1/8 of a teaspoon and weigh it. This gives me a result of 8.5 grains. I now know that it is 8.5 grains per 1/8 tsp. I need 23 grains, that is 2.710/8 teaspoons, or 0.3387 or very close to 1/3 of a teaspoon.

If you have a 1/3 teaspoon, then you will use that. If you don’t, use a 1/4 teaspoon.

If you can measure in CC, you will find that 1.5 is just less than your 23 grains. If you have the Lee scoops, the 1.6cc scoop will get you darn close.

After each test measure, remember to return the powder from the powder pan to the source so you don’t waste powder.

So now we are ready to throw a charge. Using the scoop or spoon, carefully measure into the powder pan. Let the scale stabilize. Now use the trickler to carefully bring the charge to the correct weight.

If you get it wrong, just pour a bit from the powder pan into your source, and start trickling again.

Once you have this working, you can make up your powder charges relatively quickly.

The first thing that you can do to help speed things up is to get a powder funnel. These are very common. You need one that will fit the case that you are reloading.

You also need to have a way to hold your case while you are charging it. Having a case full of powder spill out is not fun.

There are two different safe processes for charging a case. The first is to charge the case and immediately seat a bullet in it. If you put that case down, even for a second, you need to inspect the case before you seat a bullet in it. It is far too easy to double charge or not charge a case. You must make sure this doesn’t happen. Too much and you get a Kaboom! Too little and you have a bullet stuck in your barrel. Or too little, and it goes kaboom, too.

Moving a little more efficiently

This is the manual method that I use.

I have an independent stand on my reloading bench. The powder measure is mounted in that. I hold a powder pan touching the spout. I throw a charge, catching it in the powder pan. I lower the powder pan and place it on the scale.

At this point, I’m done with spoons and scoops. I can do it all with that powder measure. With some powders, I can get the throw to be consistent enough that I don’t have to trickle at all.

There is still a bit of an issue with powders that don’t like powder measures.

For some situations, I can actually mount this on my turret press. Raise the lever, throw the charge, advance to the next station where I seat a bullet, advance to the next station to crimp.

Reset the turret to dispense powder, process the next case.

Depending on the powder and the measure, this can work very well.

And Upgrade!

Those mechanical scales are wonderful. Unfortunately, they are a bit fiddly to use, a bit slow to reach a steady state, and are more difficult to remove and replace the pan.

The answer is to move to electronic scales.

The only thing that changes, is that you are now using an electronic scale. It will stabilize a little faster. It is faster to read. It is easier to put the pan on and remove the pan. All good things.

The downside is you are now trusting a magic piece of electronics. The electronic scale you buy should come with calibration weights. Use them, verify that it is reading correctly.

Many of the electronic scales come with 50 gram calibration weights. This is fine.

You don’t throw 50 gram charges. Your charges are smaller than that. So get yourself some calibration weights that are closer to your charge weights. Now check the calibration using those weights. Make sure that when the scale reads 22.1 grains, it is 22.1 grains and not 25.3 grains.

Another Upgrade

This thing is a black magic wonder. It is a combination electronic scale and motorized trickler. You tell the gizmo what charge you want and press the go button. It spins the trickler tube, depositing granules into the powder pan sitting on the scale.

The software knows how to let the scale stabilize. It will do all the right things to get you a good charge.

If it accidentally goes over, it will tell you, you return that charge to the hopper and press the go button again.

My version of this thing threw 3 charges that were over by 0.1grains in the 300+ rounds I recently reloaded. The amount of time it takes to throw a charge is just a bit longer than it take me to seat a bullet in the last case.

Safety Considerations

It is likely you are going to want to charge your case in a batch. Get yourself reloading trays that fit the cases you are reloading.

I’m trying out some universal reloading trays that hold 7 or 8 different size cases. But it really doesn’t matter who’s loading trays you use. Just use them.

Put the cases you want to charge in the tray. Start small, 5 or so.

Put the charging funnel on the first case. The tray should hold everything upright, without falling over.

Measure your charge and pour it into the funnel. Tap the funnel gently to make sure all the powder is out.

Now MOVE IT to the next case. Always move the funnel in the same direction. Don’t go back and forth. The funnel is always moving towards you (my preference), or always moving away from you. When you get to the end of a row, move to the next row.

Now you are done with this batch.

STOP

Get out your flashlight and look down the mouth of each case. You should be able to see the powder. You should be able to see if the powder levels are the same. If you are in doubt about any of them, pour the powder out, into the powder pan, and measure it.

If you’d like, take a couple at random and weigh those charges. If you don’t get the right number, figure out why. DO NOT USE CHARGES IF YOU HAVE ANY DOUBTS It doesn’t cost anything but time to pour all that powder back into the hopper and do it all over again.

They make probes that you can use to check levels. They are rods that slide into the mouth of the case. If the case has the right amount of powder, it will be in the good zone on the rod. I don’t use these, I just know about them.

Response to Comments

Slow Joe Crow says that availability and ease of use are also considerations.

He is correct. If I had my way, I would use IMR 4895 for most of my rifle loads. It has gotten expensive and difficult to find.

He mentions the extruded powders issue as well as Ramshot TAC.

The Ramshot TAC is on my list of powders to try.

Curby in full:

I have nothing to add.

CBMTTek points out some of the issues of using your own reloads for self-defense loads.

Go read it in full for the great points he makes about not using reloads in that situation.

When I started shooting, I carried SD rounds in my pistols. When I arrived at the range for practice, I put a mags worth of SD rounds down range. I trained to know what those rounds felt like and to put them all on target.

When SD rounds are difficult to find, and they are going for $1.00+ per round, it is a little uncomfortable to put 9 or 19 rounds down range.

When I use JHP reloads for both SD and range candy, because the cost difference isn’t that much, that is a real win for me.

I do have pure range candy, a few hundred rounds of 45ACP with black bullet 230gr coated cast bullets. They work fine, they are easy to load, a great practice bullet. But they aren’t the same as my SD bullets, thus the need to practice.

It’s just Boris says that they are attempting to standardize on Winchester Ranger-T SD rounds.

He picked that because that is the round that the local police are likely using.

When I started down this path, I purchased a used Glock. It had been a Maryland State Police duty firearm. The SD ammo I purchased was the same ammo they carried, at the time.

I read all the articles I could get my hands on. In Maryland, they will jack you up. Everything you can do to make your life easier in the horrible situation of having used your gun in self-defense is worth it.

I don’t live in Maryland anymore. I am not as concerned as I used to be, my balancing act falls on the “more practice” side of things.

Chris says:

Masaad always has good points. This is one that I had not considered.

Also, I read a long time ago, using reloads for self defense MAY cause you issues if it comes to court. Prosecutors COULD push the issue that you just HAD to make your own more “deadly” bullets because factory rounds wernt good enough… Factory rounds for me. And if you are friendly with local cops ask what they carry in duty pistols. Can’t go wrong using what cops use!

When I was learning and loading on Single stage – I always made sure to immediately seat the bullet after charging with powder.

Another tip if/when you switch to progressive press – if it ever hangs up. STOP. Don’t try and force the press, you will break parts, crush cases, smash bullets. When I have any kind of error I unload the press fully, lay out the cases int he order they came out of the press. Figure out what went wrong, and then placing the cases back in their proper station.