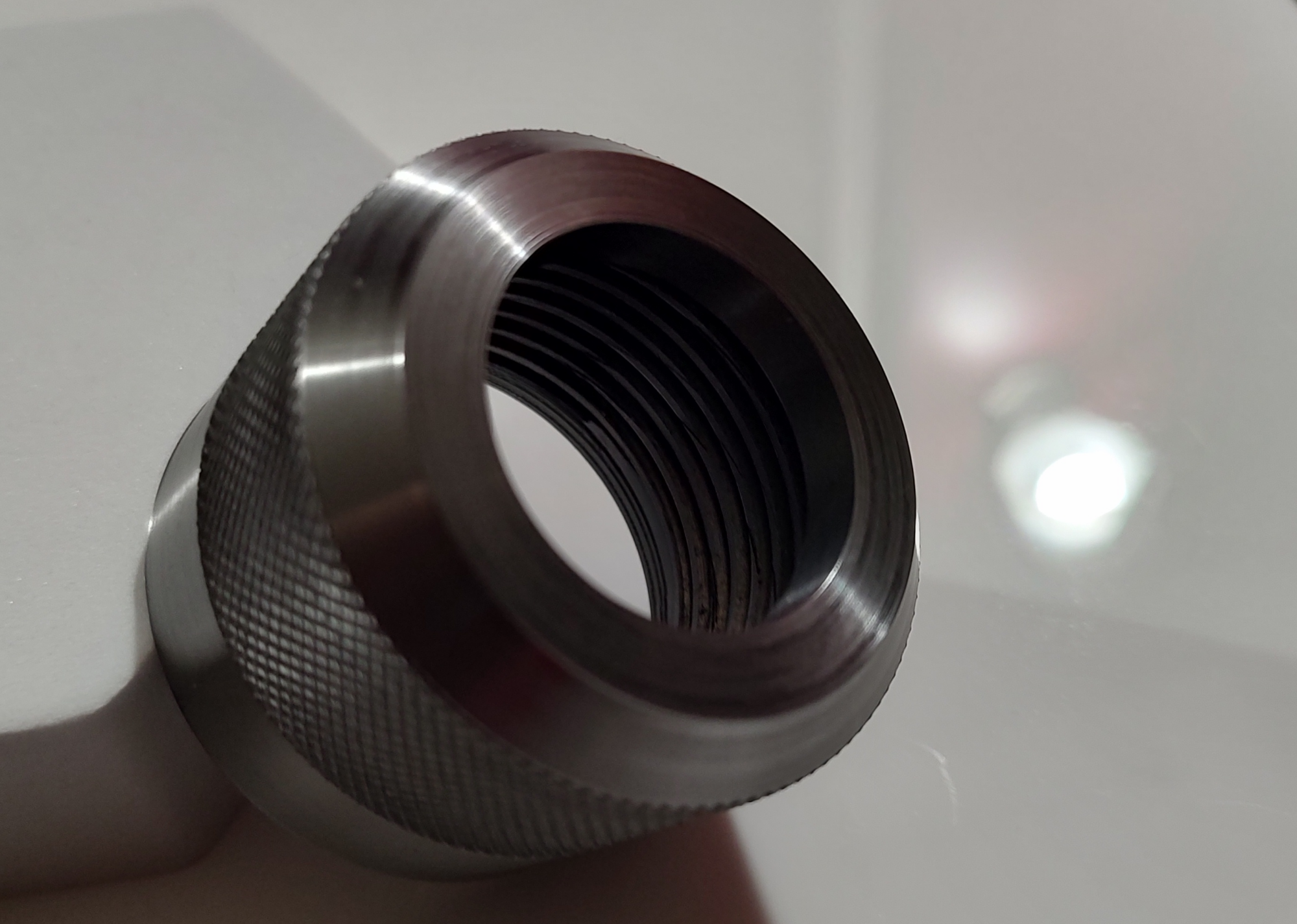

Yesterday I completed that thread protector.

This was required to finish the alignment spigot, which is required to mount the backplate to the rotary table, which is required to mount the chuck to the rotary table which is required to hold the mandrel to hold gear blanks, which is required to make gears, which are required to make the Casinator.

See, this is firearms related.

This was the first time I used an internal grooving tool. It was the first time I’ve run the lathe in reverse to do any cutting.

While there were no precision requirements for the thread protector, I still treated it as if I were making a backplate for a chuck to be mounted on the lathe. This gave me practice in measuring bores correctly, and hitting my numbers.

I am going to decide if I coat it in LPS-3 or if I give it a bluing treatment.

Looks good!

To misquote Bugs Bunny: “What’s up, Chuck?”

(Looks nice!)

Very nice! Doing knurling is a fun exercise.

I’m not sure how this protector relates to the other things you mentioned.