Review: Diamond K Brass

One of the issues I have had is that my brass continues to disappear at the range. I’ve had some luck getting range brass from friends, but not nearly as much as I want.

My last “big” score was 125 pieces of 8mmx57 Mauser for “only” $75.00. Of course, that was my frequent flyer discount along with the fact that it was part of “discount the brass, or I’m not going to buy this here $1000 rifle”.

I was pleased with my last reloading session and wanted to finish filling my ammo cans with 5.56×45. Somebody mentioned Diamond K Brass, so I went looking.

Their prices were so low that I was concerned they might be a scam. They most certainly are not.

When I buy brass from the standard places, if they tell me they are sending me 100 pieces of brass, I’m going to get 100 pieces of brass. Maybe I’ll get 101 pieces.

I took the plunge and ordered 1000+ of .223/5.56 from Diamond K. There was shipping, I was about to walk away when I did the math and decided it was acceptable at $22.00 for insured to me.

What arrived was a boat load of brass. The brass was cleaned but no deprimed. That was my first step.

There was a mix of head stamps. The mix seemed to be about 50/50 .223 and 5.56.

Of the 1000+ cases, I had 4 cases that were too damaged to use. I might have been able to rescue 2 of them, as it was just the case mouth. With a bit of time with the proper tool, I could have opened up the mouth enough for the sizing die to correct any remaining damage.

There was one .300 blackout case. There was one .22LR case. There were two cases that had no powder, but the bullet was still inside the case.

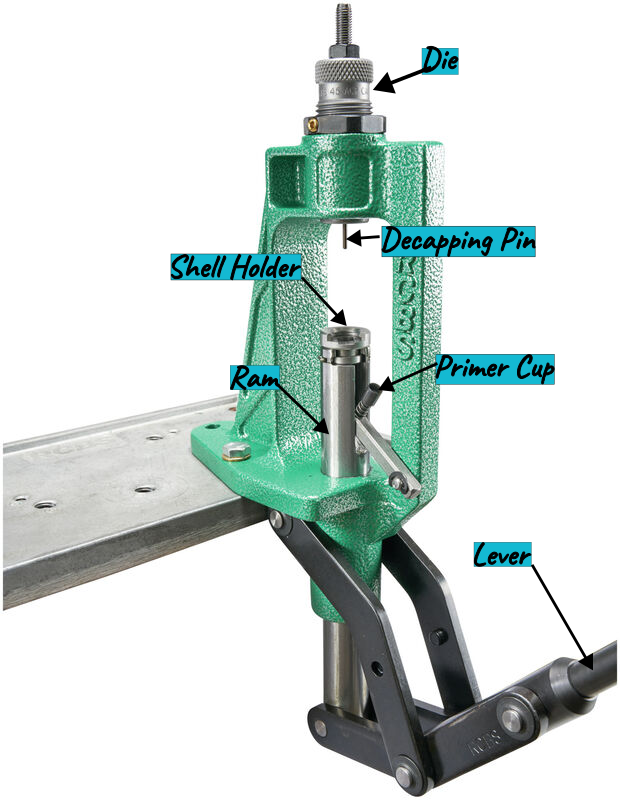

My biggest issue was that one of the head stamps has a primer flash hole that is too small. I can’t get my decapping pin to fit through to punch out the primer. I destroyed one decapping pin when I pushed too hard.

I have a tool on order to bring the flash holes to the correct nominal size. That will happen this weekend. At which time I will be able to finish decapping the cases.

Was the price right? YES. This is good-looking brass. I will be placing more orders with them shortly. Looking at 2000+ .45 ACP, 2000+ 9mm, more .223/5.56, and maybe some strange brass as well.