(1800 words)

How to open a can of worms… There are people who have the recipe they swear by. Yet, they will admit that there are other recipes that function nearly as well as theirs does. Bullets, on the other hand, have much stronger feelings.

We’ll start by breaking bullets down into two categories, bullets that transfer as much energy as possible to the target, and those that don’t.

I just finished some reloading. Many of the rounds I loaded were 55gr .224, Full Metal Jacket Boat Tail. Some were 55gr Soft Point Boat Tail.

The difference being that one had a pointy noise covered in copper. The other had the very tip, exposing the lead of the core.

Given that the size of that tip was maybe 0.080 in diameter, I did not expect to see any difference. I was wrong.

Using the super scientific test media known as “pumpkin”, I placed two small pumpkins down range and put 10 rounds into it. All hit. Nice grouping. There was significant damage to the pumpkin. It was still obviously a pumpkin.

I changed magazines, made sure the soft points were going where I wanted (rang steel). Then I went to put the last 10 rounds into the other pumpkin. I was only able to put one round into the second pumpkin.

That “soft point” round caused the pumpkin to fly to pieces. I ended up with pumpkin pieces as much as 4 yards from the point of impact.

This has shown me just how much difference there can be.

History

I’m ignoring the early rocks and pebbles that were dropped down the bore of a gun to be propelled by gunpowder. I’m starting from the first bullets made of metal.

We have to look at the metallurgy of the those early times. They were dealing with low-pressure gunpowder within the metals they could work, at the time.

They used brass and bronze for those early cannon, later moving to iron and steel. The iron and steel had to be forged to have enough strength.

The bullets for hand — held weapons had to be small enough, mass enough, and to be easily formed, and not expensive.

This meant that lead was the material used.

The next consideration was shape, they used what seemed to them to be best, round(ish) spheres. They could make molds of iron or brass, melt the lead, pour in to the molds, and get nearly round bullets of nearly consistent size and shape.

So our first bullets are round, lead balls.

Now we have to figure out how well bullets work. The bullet has to carry enough energy to penetrate the target. Once it has to hit the target, it needs to damage the target enough to kill it. The starting point is

Since the velocity(v) is limited by the pressure that can be developed to push the bullet down the barrel, the only way to increase the amount of energy carried downrange is by increasing the mass(m) of the bullet. I.e., big fat lead balls moving slowly.

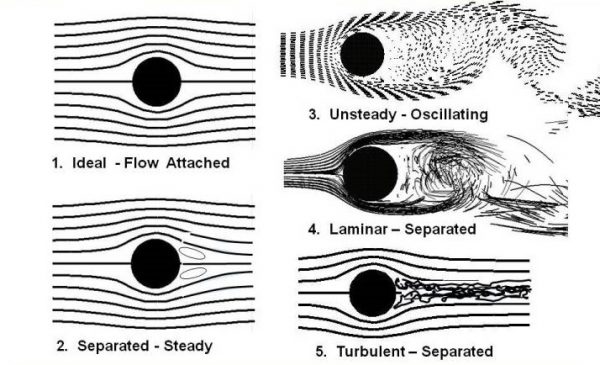

Round objects also have issues with traveling through a fluid (air). They tend to have increased drag as their velocity goes up.

As the velocity increases, the Reynolds number goes up.

The important part of that is that as the Reynolds number goes up, so does drag. This means that the faster you push a round ball through the air, the faster it slows down.

Having more mass maintains the energy.

It turns out that if you change the shape from a sphere into a cylinder like shape, it performs better. The flow remains laminar at higher speeds.

The tips of these cylinders had different shapes, flat, rounded, pointed and conical.

IBD was charged with getting the projectile out of the barrel. LFD was charged to with getting it from the barrel to the target. TBD was charged with telling us what happens when the projectile impacted the target.

When the early developers of ammunition were working on the issue, they concentrated on launch and flight as long as terminal ballistics were “good enough”>

Besides the launch and flight characteristics, They started working on the interior ballistics in the mid-1800s. They were looking at two major considerations, getting the bullet to more firmly engage the rifling and to capture more of the pressure developed by the black powder.

This led to the development of the Minié ball. This bullet incorporated all the best features of bullet design, to that point. It was cylindrical, with a rounded cone tip, grooves for more aerodynamic flight, and a conical, hollow base. The hollow base caused the base of the bullet to expand into the rifling, giving a better gas seal and better engagement, increasing velocity and accuracy.

With the advent of the metallic cartridge, bullets had to meet another requirement, they had to be seated in a case and to release correctly when fired.

Most of the bullets of this early metallic cartridge era were round nose, lead, with flat bases. Much better than balls, still not great.

As our ability to instrument the firing of different bullets, we were able to develop better and better shapes. The Spitzer being one of the best, aerodynamically speaking.

One of the great things about lead bullets is how soft it is. When it hits, it deforms and transfers much of its kinetic energy to the target. One of the disadvantages of lead is how soft it is. When it is accelerated too rapidly down a rifled barrel, it shears parts off rather than taking on spin.

If you push a lead bullet too hard, it loses flight stability and velocity.

The answer to the issue of being too soft was to in case the lead bullet inside a harder copper jacket.

Terminal Ballistics

Once we knew how to launch a bullet and how to get the best aerodynamics out of a bullet, we needed to make sure that it was doing what was required to the target.

This comes down to balancing energy transfer against penetration. The better a bullet penetrates, the less energy it is transferring. The better it transfers energy, the less penetration capabilities it has.

We also have the issue of sometimes needing good penetration on the first hit and good energy transfer for the second impact. I.e., we want to shoot through the glass windshield without transferring all the energy to the glass. When the bullet hits the driver, we want all the energy to transfer to the driver.

We could spend megabytes of text on different targets vs. different bullet designs. That’s now what this article is about.

We are concerned with a very few different targets. Soft skin targets at 50 to 200 yards distance. Deer, raccoons, unarmored humans. Soft skin targets at 20 yards or fewer. Raccoons, humans and such. Soft skin targets, at 20 yards and less, humans. And mild armored targets at ranges out to 200 yards.

For soft skin targets, we want good terminal ballistics. This means some type of point on the bullet that causes rapid expansion when the target is hit.

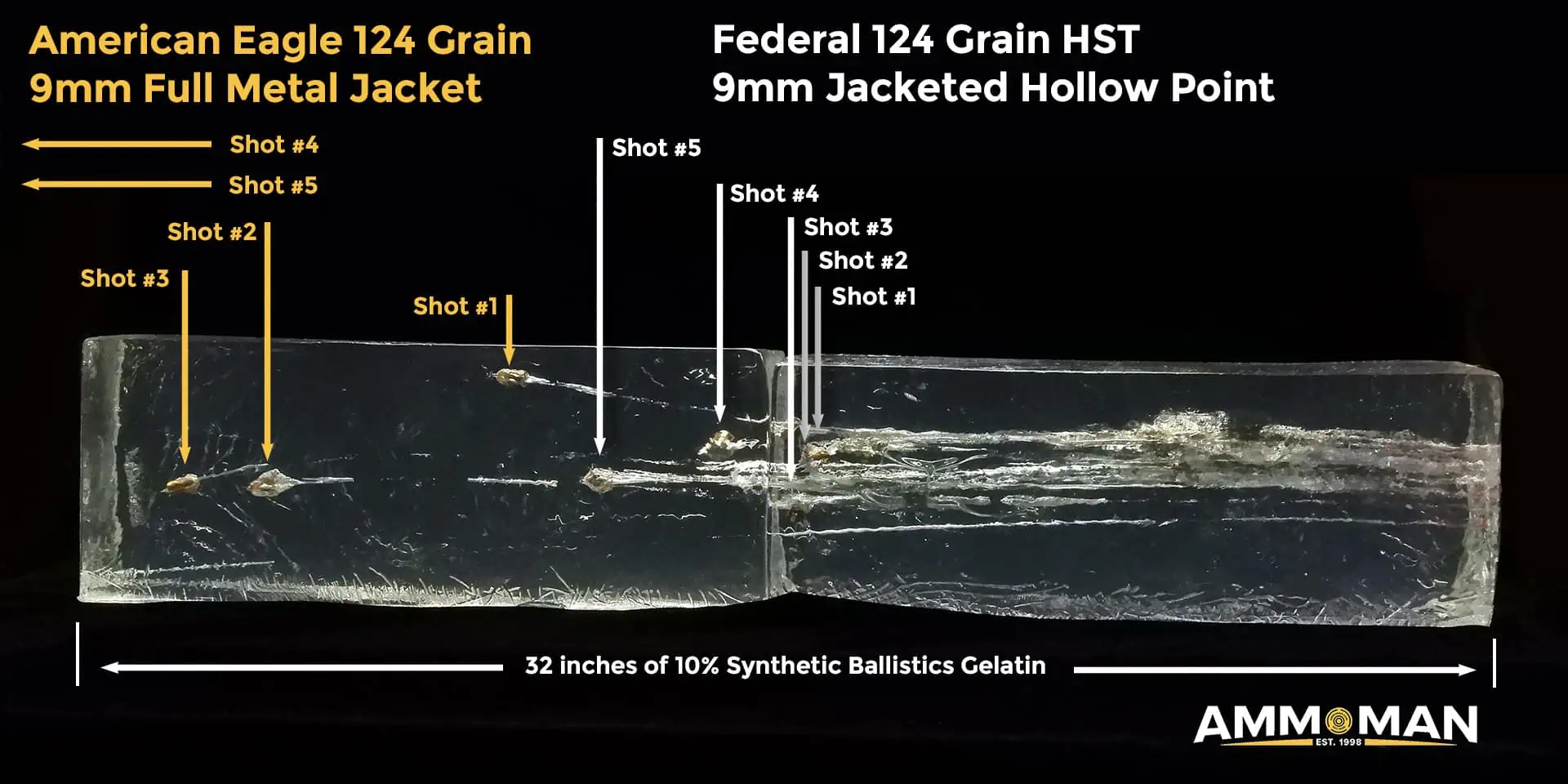

Stealing an image from AmmoMan.com:

The full metal jacket (FMJ) bullets had better penetration. Almost 32 inches, in some cases. That means it would go through an animal. All the energy that is carried out the exit wound is energy that didn’t go into stopping your target. On the other hand, the Jacketed, Hollow Point (JHP) rounds stopped at around 16 inches. This is still enough to pass through some animals, but more energy is transferred to the target.

At higher velocity, such as out of a rifle, the energy transfer difference is significantly more.

When you want to stop a target, you want energy transfer.

Velocity v. Mass, a trade-off?

When we transitioned to smokeless powders, the pressures went up. This allowed for faster bullets. Having a faster bullet helps with accuracy and the ability to reach out and touch somebody at range. To delivery unhealth care as needed.

At the same time, we want to hold our mass at a reasonable value. This means longer bullets.

So let’s compare some kinetic energy!

We are going to toss some 55grain bullets downrange at 3100 ft/second and some 230grain bullets at 850 ft/second.

Our base equation is:

This shows that our faster moving, lower mass projectile delivers 3.2 times as much energy at the muzzle.

Given the different shapes of the bullets, the drag is much higher on the 230grain bullet. It slows faster.

A 230gr JHP into ballistic gel had a penetration of around 16 inches. The M193 dumped all of its energy into a gel block in 12 inches. This is not the results I expected. I keep learning

Here in ends this part of the discussion. My example of M193 vs. 230gr JHP .45ACP came out entirely different from expected.

Regardless, you want your bullet to dump energy into your target. Turns out the AR-15 platform delivers, even with FMJBT.

Costs

In general, FMJ bullets are cheaper than JHP or any of the fancier expanding bullets. Not as much as you might think when dealing with reloading.

Hornady 45ACP+P 230gr XTP-JHP runs $1.30/round, yet that bullet is only $0.33/bullet compared to the Hornady FMJ at $0.29 per round, or $0.04 more.

What this means, is if you are reloading, the cost of using high quality expanding bullets is not that much more.

If you go to a company that produces and sells bulk bullets, you can often get your bullets at great prices, less than the name brand FMJ bullets.

In addition to just buying bulk bullets, to get your prices down. It is possible to cast bullets. This can reduce your costs even more. If you do cast bullets, know that you will need to prepare them so they give you the best results. I powder coat my cast bullets.

There are also companies that sell cast bullets which are coated or plated.

Conclusion

Pick your bullet based on the caliber you are reloading, followed by the type of shooting you are doing.

If you are making “range candy”, consider paying a few cents more per round to have rounds that perform well against animals.

Regardless of all other considerations, make your loads consistent. By this, I mean, if you are a 45 sort of man, and you buy off the shelf range candy, standardize on 230GR bullets.

Don’t be afraid to trade mass for velocity.

Most importantly, have fun, know you’ll send more rounds downrange when you can afford to shoot.

Postscript

This article was going in a different direction when my verification process stopped me abruptly. I do try to verify every fact that I put in my articles. For every hour I spend writing, I’ll spend 1.5 to 2 hours doing research. This is the primary reason I keep doing Tuesday Tunes and Friday Feedback. It gives me two days a week when I don’t have to dig into the swamps of court fillings.

It also means that it is often faster for me to write an opinion piece or something where I consider myself to be knowledgeable about.

I know lots about bullets and bullet design. I know how I pick my bullets. While I love my .45ACPs, that is mostly because I love the feel of my 1911s. I don’t like the feel of my Glock. I know that 9 mm will perform about the same as .45ACP in terminal ballistics.

The bullet that exploded the pumpkin must been one of those ar14 bullets made with C4…. Heh heh heh.. often times actual real tests surprise the heck outta ya. Good stuff.

You should add a note that ballistics gel is not a 1:1 ratio with living tissue. It’s just consistent test media for comparisons of bullets. For example, just human skin is as tough as 2″ of gel. So your JHP example wouldn’t over penetrate a human.

Right, the optimal gel penetration was developed in reverse. People got shot. Some died, some didn’t. They asked the brand/type for those that “stopped their criminal behaviors”. They started shooting those brands of bullets into gelatin. From that, they determined the 12-18″ penetration in gelatin as being optimal.

<i<"Round objects also have issues with traveling through a fluid (air). They tend to have increased drag as their velocity goes up."

Which is why open wheel race cars have all that multi-faceted aerodynamic carbon fiber metastasizing all over the front end (including the body shell behind the front wheels – it’s there in an attempt to reduce turbulence and decrease the low pressure area behind the wheel by restoring smooth laminar flow). To the human mind, something round is something that rolls, reducing friction; to air it’s a vertical piece of plywood, and as airflow “splits” around it the ground is a barrier which induces wild variations in airflow – fluctuating turbulence, compounded by angular intrusion into the airflow (“steering”). Were the rotating wheel suspended 10 feet up instead of resting on the ground the airflow would be more consistent (substantially laminar) but it would still perform like that piece of plywood.

The “unsteady – oscillating” picture is the classic one of a round bullet without spin (smooth bore). I don’t know if there are good videos of that. But you can see it well if you find a good slow-motion video of a “knuckleball” pitcher at work. It’s quite weird to see the ball flying utterly without spin, and zigzagging randomly due to the unpredictable airflow over the non-rotating ball. Put any kind of spin on the ball and its path becomes non-random and largely predictable. Not necessarily straight, depending on the rotation axis, but not random.

One of my all time favorite magazines was the long defunct “Precision Shooting”. I learned a great deal from them and still have a few copies in a dusty box somewhere.

The most critical moment in a bullet’s flight is when it breaks contact at the muzzle. The propellant gas comes rushing out, and this must be absolutely consistent and uniform. Flat based rifle bullets are more accurate boat tail bullets, out to around 200 yards. That’s why the benchrest shooters use them to shoot insanely small groups where center to center hits are measured in tenths of an inch. The reason is that it much easier to manufacture a precise flat base than a precise boat tail. That said, with today’s technology, the difference these days is pretty small. Where boat tails come in their own is a distance. See the above discussion of drag.

Buying cast bullets. Here is a good outfit–

https://www.missouribullet.com/technical.php

Class III time sink, articles by the late Major Dick Culver, USMC–

http://www.jouster2.com/jouster_tales.html

Here are two–

http://www.jouster2.com/sea_stories/when_the_tin_can_changed_history.pdf

http://www.jouster2.com/sea_stories/end_of_an_era.pdf

1911 vs Glock. Agreed. Glocks feel like a 2 X 4 in my hand. Not faulting them or saying I can’t shoot them well. They are excellent tools and are well proven. All who have come since stand on Glock’s shoulders. That said, I bought one of these–

https://www.canikusa.com/tp9sf

My first ever plastic fantastic Tupperware pistol. IMHO, it is everything Glock should have evolved to 20 years ago.

Although it has more to do with the cartridge than specific bullets, ballistic coefficient is worth keeping in mind for long range performance. The short form is long skinny bullets like 6.5 Creedmoor work better than short stubby bullets. The long form is a lot of physics and ballistics and some bullets for a given cartridge have a higher BC so choose according to your objectives.