The Custom Pocket Tool Kit

I hadn’t really explored this option until now so I started down the rabbit hole, and boy what a rabbit hole it is. There are innumerable videos on YouTube about what people allegedly carry in their pockets and the infinite utility they find out of random and weird tools and gadgets. Frankly, I think a lot of this is overstated, but for sure there are weird and unique little things that people have/do that help them do their specific weird/unique little thing.

After contemplation and viewing some other people’s EDC for ideas, I determined that a compact driver of some sort with a variety of bits and an extension could fit in a small pouch or case and I could easily fit a couple of other nice to haves in that form factor. And while the videos were sometimes questionable, it did help me narrow down specific tools that I wanted. I settled on the following for the kit:

-

This is a nice little kit packed with tools in a small form factor make for biking. The standard ¼” bits can be used in the driver as either a ratchet at the ratcheting end, or on the handle end as a standard screwdriver. It included a nice assortment of bits and a small extension. I swapped around the ¼” bits to have a selection of 11 bits I wanted and ditched the included tire tool.

Klein Tools 7 in 1 Extension/Nut Driver Set

-

A wonderful tool that add not only a long ¼’ hex extension that is compatible with anything that accepts standard ¼” bits, but ingeniously has three nut drivers that service six different nut sizes that slip over the extension for storage. Quite the “force multiplier”!

-

These 4” pliers are all the rage for the EDC crowd for some reason. I don’t quite get it myself, but figured, what the hell, I’ve got room in the kit to throw those in and being small and flat they don’t really add any bulk.

-

A cheapo pouch to hold everything together.

All assembled, this was a pretty handy kit that was small but with decently big capabilities. It was however a little more bulky than I was hoping for and because of this, I couldn’t quite figure out what to do with it/where to put it.

First and obvious thought is to stick it in a front pocket, but front pocket space is already at a premium. Knife, keys, another set of key, pen, coin, YubiKey, and speed loaders go into one front pocket. Phone, flashlight, and magazine go into the other pocket. There wasn’t really any space for anything else. That leaves the back pockets.

One is occupied by my wallet and the other with my work ID in a hard plastic card protector. I could conceivably do something else with my ID and put the kit in my other back pocket. Now my wallet does come out every time I sit down at my desk along with pen, phone, and YubiKey, so I’m not averse to the idea of removing things from my pockets for comfort. However the idea of taking yet another thing out of my pocket, and one that seemed as though it would be prone to snagging, was not appealing.

With no place to put the tool kit it went unused for months, sitting in my valet tray waiting for its time to leave the house with me on my daily adventures. I even eventually moved everything into the Topeak case, which smoothed the snag potential out a bit, and still that time never came; I just couldn’t figure out where to put the thing.

With this tool kit sitting for months with nowhere on my person to put it, this ultimately was the only EDC custom tool kit I toyed with and assembled. I came to the conclusion that such a kit was ultimately stupid for my purposes, and I could fulfill the desire carrying more extensive tools every day by simply making a small tool kit that I keep in my bag that goes to and froe every day.

Defeated and tangential project to make a small tool kit for my bag completed, I set about reevaluating my requirements again. What did I actually really need on my person? Most of all the wants and extras were filled by the tools in my bag and really, if I needed anything in there to complete a quick field task, it wasn’t actually a quick field task anyways. By focusing on the key tool, the screwdriver, I settled on these requirements:

-

A screwdriver that takes standard ¼” driver bits and holds at least one spare. No proprietary bits!

-

Must fit in my pocket and be roughly the form factor of a pen or CR123 sized flash light.

The custom pocket tool kit in its first incarnation.

Ahh that’s better. The custom pocket tool kit in its final and compact form taking residence in the recycled Topeak case.

The Purpose Built Pocket Driver

And so, the search for the purpose built driver was born. There are plenty of screwdrivers out there that hold bits in the handle, some even with a shank that collapses into the handle, but they are all too bulky. Comfort and annoyance aside, walking around the office with a perennial bulge in my pants might illicit the wrong sort of attention as well so a better solution was required.

Searching about there are numerous pen sized drivers out there, all of varying design. Many used double sided precision sized bits, both details I wasn’t keen on. Many take ¼” bits, but are quite bulky to store numerous extra bits. Many rely on bit storage being detached from the driver; attractive because you can hold more bits, but now you have two disconnected things and the bits are exposed to rub against whatever else in in your pocket. And there are even some that take standard bits, but are too small. Much searching and analysis paralysis narrowed it down to the following options. I want to stress, though I ultimately settled on one of the following for my needs, these all appear to be nice products and all sat in my shopping cart at various points of “screw it, I’m going to just buy it”. At the very least, I’m trying to say, hopefully it gives you all some ideas if you are looking like I was.

OK idea. Not enough reach for me. There’s tons of different versions of drivers that go on a key ring. I don’t want further bulk on my key chain though. Pass.

Technician’s Pocket Screwdrivers

OK idea. Not wild about not being able to customize bits. Zillions of similar items from various manufacturers. Pass.

Appealingly sized and lots of function, I can overlook the double sized bits. However, without an extension it would be practically useless for me. It is possible this can be modified to hold an extension on one side, and move a third bit to the other, but it isn’t clear if this will impact the ability to close the handle and keep it closed without adding a rubber band or the like to it. I’m not interested in having something sticky and grippy like that in my pocket. Pass for now.

Titanium Multi Bit Screwdriver

I REALLLLLLY like this. Good reach and lots of bits. Handy magnetic holder for bits. Sadly, too bulky; a 1” handle is just not gonna work for keeping in my pocket. Sad pass.

I also REALLLLY like this one. ½” handle diameter is doable. Spinner end is nice. But bit storage requires rubber bands which are sticky, grippy, can roll off, and can break. There are a number of tools similar to this in varying shapes that use rubber bands or o-rings to keep bits secured to them. Many pry bar/driver combos (EDCers are in love with the pry bar too for some reason). Another sad pass.

Zillions of options for this sort of tool. This became an attractive backup option, but as I was first looking at these I was not into the idea of precision bits. Pass, but keeping it in mind.

James Brand Cache River Keychain Screwdriver

There are a few options for a tool of this design/style that each hold 3-4 bits I like it and was almost sold on it, but ultimately decided it was too short for what I really wanted. Pass, but keeping in mind.

Wheeler makes two versions of this, a micro pen sized one and a slightly larger diameter one. These look great and I was soooo close to being sold on the micro one until I read reviews. These take proprietary bits, which can be forgiven, but how they work cannot. These tools use a push through design with a stop at the end to hold the bits. You must push each bit through the bottom of the handle to advance to the next bit so a typical magnetic holder is not possible and the grip system will not work with standard bits. Reviews and questions also seem to overwhelmingly indicate that the bits don’t stay very well in the tool. Hard pass.

Big Idea Design Driver Offerings

Big Idea Design offers a number of EDC bit drivers in various shapes and forms. I almost settled on the Ti EDS II or the Bit Bar Inline. Ultimately from my experience with the Kershaw Select Fire, I decided I wasn’t sure if the Ti EDS II was long enough or if the handle bulk/shape would restrict access and I didn’t like the square shape of the Bit Bar Inline. Pass, but keeping in mind.

36 in 1 Precision Pocket Screwdriver

This is first tool I actually bought after searching about. While I wasn’t sold on the precisions or double sided bits at first, I decided since this just had so many options because of it, I would give it a shot. I also like that the cap was a spinner cap and the body was hex shaped for better grip. Most importantly though, it looked like I could modify the storage system to remove some bits up one side and add an extension.

The bits are held internally with magnets inside of an open honeycomb frame. The magnets ride around a central shaft that connects the top to the base and the honeycomb slips over the magnets while the dividers slip over the internal shaft.

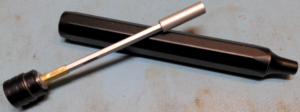

I began my modifications by cutting slots in the internal dividers to allow an extension to lay against one side of the honeycomb. The extension required trimming to length and a bit of grinding on the end that accepts the bit so it wasn’t too big to fit in the body of the screwdriver. This worked OK, I couldn’t make the end that accepts the bits much thinner than I had without basically making it useless, and it was just thick enough that everything would not slip together 100% smoothly or in perfect alignment; the end of the extension that accepts the bits lays slightly proud of the dividers.

While this first modification worked, it wasn’t great so I set about scheming. I came up with the idea to remove the central rod that everything rested on and replace that with the extension itself. A new retainer for the the bits can be 3D printed as one piece that slips over the extension and allows the bits to snap into it without requiring a magnet to hold them in place. The end of the extension that accepts the bits can then slip over a brass rod/screw in the tip of the body that is either glued in or held in place with a magnet and the cap end can have a piece of hex tubing glued in place that will allow the extension to slip into it. This design would also allow the cap to still rotate and act as a spinner. Everything all mocked up on paper and in my head, modifications were made and it all worked out just as planned! That plan did however, not anticipate one thing; the cap was connected to the bottom divider magnetically via the the central rod, which we not removed, so the cap will not presently stay affixed.

There are a couple of solutions to this that I can think of off hand, connect the new central extension to the magnet in the tip more permanently in some way so the magnet pulls out with when all the guts are extracted. Create a spring clip/clasp/retainer of some sort that fits around the body and allows the cap to clip into place. This problem requiring solving, coupled with the fact that I still need to model and have printed the new internal bit holder, let me to temporarily or semi permanently abandon this project and seek alternatives.

The center rod replaced with a bit extension.

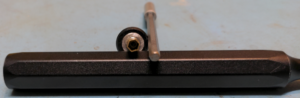

The existing connection point for the original center rod was cut down then a piece of brass hex stock glued over it to create a slot for the bit extension to slip into.

A view showing what the end of the bit extension slips over inside the barrel. Left picture shows it in the barrel where it rests at the tip end. The right picture shows the assembly removed. The bottom is a spacer to stick to the magnet in the tip of the barrel with the doughnut magnet stuck to the top it, it sticks in the barrel nicely.

This shows how everything sits inside the barrel assembled. Just missing the as yet designed bit storage that would go around the bit extension.

A cool tool for building a ratchet kit around is the Harbor Freight Icon mini-ratchet. The kit comes in a box that’s more bag than pocket sized but it’s worth finding a smaller case.The selling point is the ratchet and extension work together to form a ratchet with extension, ratchet with a longer handle or a T handle.

https://www.harborfreight.com/locking-flex-head-ratchet-and-bit-set-35-piece-58074.html

Since it’s more portable I keep an old Leatherman PST with 1/4″ bit adapter in my work bag and the Icon lives in the garage.

Those kits are great, lots of features for the price! I will likely get one to add to my bag EDC tool kit.

Modifying the 36 in 1 screwdriver made me say I really need a lathe. I’ve been thinking of getting a small bench top one for some time and this pushed that up priority wise; cutting pieces to modify this would have been stupid simple. Instead, I used my battery powered drill with a quick release clamp on the trigger and some files to make a ghetto lathe and do some sketchy turning. It worked, but precision is far enough removed from that setup that they could safely marry if you catch my meaning.

I like this article series a whole helluva lot. Thank you for taking the time to do the research.

My only word of caution is the bit drivers: Check the inside of the bit driver before use. I’ve found it can take pliers and a vice (extreme example) to remove the bits if water/oil/dirt/debris gets on the bit-and-driver or in the driver itself.

Glad you are enjoying it!

.

Good bit of advice. On the precision drivers I’ve found the vary quite a bit quality wise as well, some fit bits nicely and others are sloppy.